Parker Hannifin Corporation offers a wide range of hydraulic pumps under their Parker brand. Parker pumps are known for their high quality, reliability, and performance.

Here are some key points about Parker hydraulic pumps:

Types: Parker offers various types of hydraulic pumps, including gear pumps, vane pumps, piston pumps, and axial piston pumps. Each type has its own characteristics and advantages, catering to different application requirements.

Gear Pumps: Parker’s gear pumps are known for their compact design, high efficiency, and quiet operation. They are suitable for a wide range of applications and are available in both external gear and internal gear configurations.

Vane Pumps: Parker’s vane pumps are recognized for their smooth and quiet operation. They offer excellent performance, efficiency, and versatility. Vane pumps are available in single and double vane configurations.

Piston Pumps: Parker’s piston pumps are designed to handle high pressures and deliver precise flow control. They are available in axial piston and radial piston configurations. Axial piston pumps are known for their high power density and efficiency, while radial piston pumps are suitable for heavy-duty applications.

Variable Displacement Pumps: Parker offers variable displacement pumps that allow for adjustable flow rates to match system demands. These pumps provide energy savings and precise control by varying the displacement according to the requirements of the hydraulic system.

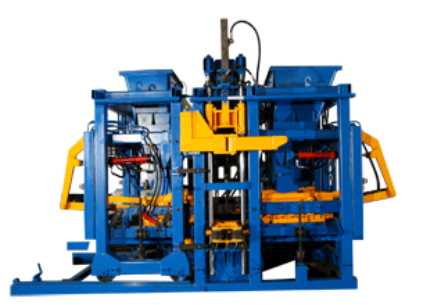

Applications: Parker hydraulic pumps find applications in various industries, including mobile equipment, industrial machinery, construction, agriculture, material handling, and more. They are used in hydraulic systems to generate fluid flow and create hydraulic pressure to operate cylinders, motors, and other hydraulic components.

Customization: Parker also offers customization options to tailor hydraulic pumps to specific application needs. They can provide pump modifications, special configurations, or integrated solutions to meet unique requirements.

When selecting a Parker pump, it is important to consider factors such as flow rate, pressure rating, operating conditions, compatibility with the hydraulic system, parker pump catalog and specific application requirements. Consulting with Parker representatives or experts in hydraulic systems can provide valuable guidance in choosing the appropriate Parker pump for your application.

For detailed information about specific Parker pump models, specifications, and performance data, I recommend visiting the Parker Hannifin Corporation website or contacting their customer service for access to their pump catalog or technical documentation.

Here are some additional details about Parker hydraulic pumps:

Advanced Technologies: Parker incorporates advanced technologies into their hydraulic pumps to enhance performance and efficiency. For example, they utilize precision manufacturing techniques, advanced materials, and innovative designs to optimize pump performance, reduce noise levels, and improve overall system efficiency.

Pressure and Flow Range: Parker hydraulic pumps are available in a wide range of pressure and flow ratings to accommodate various applications. They offer pumps with different pressure ratings, from low-pressure pumps suitable for light-duty applications to high-pressure pumps capable of handling demanding industrial and mobile hydraulic systems.

Multiple Configurations: Parker hydraulic pumps are available in multiple configurations to meet specific application requirements. They offer single-stage and multi-stage pumps, fixed displacement pumps, variable displacement pumps, and combination systems that integrate multiple pump types for enhanced functionality.

Control Options: Many Parker hydraulic pumps offer different control options to provide precise flow control and system performance. These control options may include pressure compensation, load sensing, proportional control, and electronic control capabilities. They allow for better responsiveness, energy efficiency, and system optimization.

Durability and Reliability: Parker is known for manufacturing durable and reliable hydraulic pumps. They use high-quality materials, advanced manufacturing processes, and rigorous quality control measures to ensure their pumps can withstand harsh operating conditions, maintain consistent performance, and have a long service life.

Service and Support: Parker provides comprehensive service and support for their hydraulic pumps. They offer technical documentation, installation guidelines, maintenance instructions, and troubleshooting resources to help users properly install, operate, and maintain their pumps. Additionally, Parker has a global network of authorized distributors and service centers that can provide assistance, spare parts, and repairs when needed.

Compliance and Standards: Parker hydraulic pumps conform to industry standards and regulations to ensure safety and performance. They meet or exceed various standards, such as ISO, SAE, and specific industry-specific certifications, depending on the pump type and application.

It’s important to consult the specific product documentation, catalog, or contact Parker directly to get the most accurate and detailed information about their hydraulic pumps. They can provide specific technical specifications, performance data, and application guidance based on your specific needs.