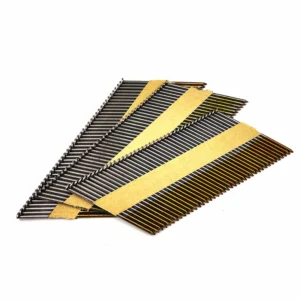

Paper nails and plastic nails refer to the type of collation material used to hold the nails together in a strip or coil.

Here are the main differences between paper nails and plastic nails:

- Collation Material: Paper nails have a collation strip made of paper, while plastic nails have a collation strip made of plastic. The collation strip holds the nails together and facilitates their feeding into a nail gun.

- Durability: Plastic collated nails are generally considered more durable than paper collated nails. Plastic collation is more resistant to moisture, which can cause paper collation to degrade or become weak. Plastic collated nails are often preferred for outdoor or high-moisture applications.

- Compatibility: Paper collated nails are compatible with certain types of nail guns that are designed specifically for paper collation. Plastic collated nails are compatible with nail guns that are designed for plastic collation. It’s important to use the appropriate collation type for the nail gun you are using to ensure proper feeding and operation.

- Jamming: Both paper and plastic collated nails can occasionally experience jamming in a nail gun. However, plastic collated nails are generally less prone to jamming due to their more rigid and durable nature.

- Availability: Both paper collated nails and plastic collated nails are widely available and can be found in various lengths and types suitable for different applications. The availability of specific nail types may vary depending on the region and the specific nail gun model.

- Cost: The cost of paper collated nails and plastic collated nails can vary. Plastic collated nails are often slightly more expensive than paper collated nails due to their enhanced durability and moisture resistance.

When choosing between paper collated nails and plastic collated nails, consider the specific requirements of your project, the compatibility with your nail gun, paper vs plastic collated nails and the environmental conditions in which the nails will be used. Consult the manufacturer’s recommendations and guidelines for your nail gun to ensure you select the appropriate collation type for optimal performance and reliability.

Here are some additional details about paper collated nails and plastic collated nails:

- Strip Configuration: Both paper collated nails and plastic collated nails are typically arranged in a strip or coil format. The nails are attached to the collation material at regular intervals, creating a continuous chain of nails. The strip or coil configuration allows for efficient loading and feeding of nails into the nail gun.

- Nail Gun Compatibility: Nail guns are designed to work with specific collation types. Some nail guns are compatible with paper collated nails, while others are designed for plastic collated nails. It’s crucial to use the correct collation type that matches your nail gun to ensure proper operation, prevent jamming, and maintain safety.

- Environmental Considerations: The choice between paper collated nails and plastic collated nails may depend on the environmental conditions of the job site. Paper collation is generally more susceptible to moisture, humidity, and exposure to the elements. If you’re working in outdoor or high-moisture environments, plastic collated nails may offer better durability and resistance to degradation.

- Jamming Prevention: While both types of collation can experience occasional jamming, the rigid nature of plastic collation tends to reduce the likelihood of jams occurring during nail gun operation. However, proper maintenance and handling of the nail gun, as well as using high-quality nails, are essential practices to minimize the risk of jamming.

- Nail Extraction: When it comes to removing nails or dismantling structures, plastic collated nails can be easier to extract compared to paper collated nails. The plastic collation can be cut or broken, allowing for individual nail removal. Paper collated nails, on the other hand, may require more effort to remove from materials.

- Job Site Efficiency: Both paper collated nails and plastic collated nails contribute to improved efficiency on the job site compared to hand nailing. The collated format allows for rapid and continuous nailing, reducing the time and effort required for fastening tasks. This can lead to increased productivity and cost savings.

Remember to follow the manufacturer’s guidelines for the specific nail gun and collation type you are using. Proper training in nail gun operation, safety procedures, and maintenance is essential to ensure safe and efficient use of collated nails.

Ultimately, the choice between paper collated nails and plastic collated nails depends on factors such as nail gun compatibility, environmental conditions, and personal preferences. Consider the specific requirements of your project and consult with professionals or local suppliers for guidance on selecting the appropriate collation type for your needs.